How To Manage CDMOs: Best Practices For Development And Manufacturing

A productive sponsor-CDMO relationship requires ongoing and proactive management to ensure consistent quality, efficiency, and long-term success. Effective oversight strategies strengthen collaboration, mitigate risks, support scaling efforts, and enable optimal program outcomes.

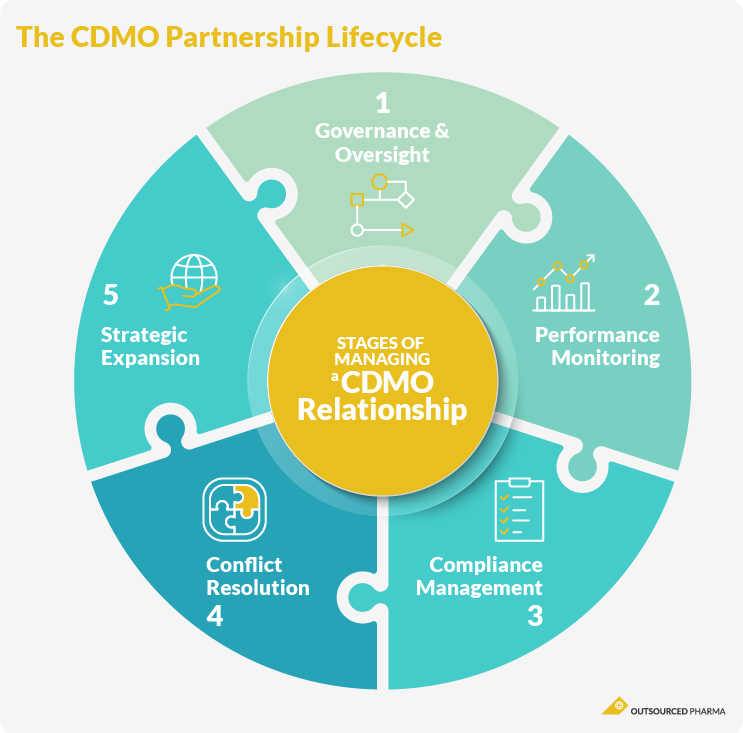

This is the final installment in our series on working with CDMOs. (To start at the beginning, visit our Outsourcing 101 page.) This guide shares best practices for managing an active CDMO partnership and strategies for handling challenges, including:

- Establishing Governance And Oversight For An Effective Partnership

- Building Effective Project Management And Performance Monitoring Strategies To Ensure Compliance

- Handling Challenges And Conflict Resolution

- Expanding And Scaling The CDMO Relationship

- Frequently Asked Questions (FAQs)

Establishing Governance And Oversight For An Effective Partnership

Effective CDMO management begins with a thorough governance framework that includes proactive strategies to create and maintain a mutually beneficial partnership.

Defining A Governance Framework

A well-structured governance framework establishes expectations and control over outsourced drug development and manufacturing activities, setting the stage for project management.

First, the framework delineates the sponsor and CDMO's roles and responsibilities. Frequently, this includes a joint steering committee with representatives from both parties to provide project oversight, issue resolution, and strategic alignment.

Additional stakeholders from key departments, including research and development, regulatory, quality, legal, and supply chain, should also be engaged to ensure comprehensive, ongoing oversight. Regular governance reviews are established to evaluate project milestones like process development, technology transfer, and GMP manufacturing readiness.

The governance framework includes quality agreements that align with regulatory expectations, such as ICH Q10 and FDA guidance, and specify audit rights, change control procedures, and each party’s responsibilities.

Additionally, pre-defined escalation pathways provide a roadmap for both parties to address risks, delays, or disputes proactively. These pathways identify decision-making thresholds, designate responsible contacts at each escalation tier, and outline response timelines to ensure timely resolution and prevent project disruptions.

Balancing Oversight With CDMO Autonomy

All relationships, even complex sponsor-CDMO partnerships, are built on trust. Unfortunately, a lack of trust can drive sponsors to micromanage their CDMO partners, but excessive control often backfires and slows the CDMO's progress.

On the other hand, too little oversight exposes the project to compliance and quality risks. A risk-based "trust but verify" approach balances the sponsor's need for operational oversight with the CDMO's need for autonomy.

Risk-based approaches weigh the product's complexity, the process's criticality, and the CDMO's compliance history to determine an appropriate level of scrutiny. Sponsors should allow CDMOs to operate within agreed parameters but still conduct audits and performance reviews while maintaining a clear data governance framework.

Key performance indicators (KPIs) include batch success rates, deviations, delivery timelines, and adherence to specifications. Allowing CDMOs the flexibility to choose how they meet these deliverables, provided they stay within regulatory and quality frameworks, may encourage efficiency and innovation.

Finally, sponsors should understand when and what issues merit escalation, such as those that impact critical timelines, regulatory compliance, or product quality. Otherwise, sponsors should encourage CDMOs to manage routine challenges within their scope of responsibility, and work with your project management team.

Establishing Communication Channels

Communication is a cornerstone of a successful partnership. Communication strategies should be intentional and structured to enable quick decision-making and issue resolution.

Generally speaking, the more information that you and your CDMO can share, the better the outcomes.

The project plan should include regularly scheduled meetings and interactions, including daily standups during critical phases, weekly status calls for progress updates, and monthly project reviews for broader oversight.

Clearly defined escalation pathways with designated contacts and defined response times allow companies to handle emerging challenges swiftly. Secure collaborative platforms facilitate document exchange, project tracking, and workflow transparency.

Sponsors should promote cross-functional communication among technical, quality, regulatory, and operational teams. This integration ensures that both organizations are aligned in the project's execution and that potential problems are proactively identified and addressed.

Building Effective Project Management And Performance Monitoring Strategies To Ensure Compliance

Ongoing monitoring ensures that the CDMO fulfils its development and manufacturing responsibilities while complying with regulatory requirements.

The Role Of Project Managers In CDMO Partnerships

Project managers are pivotal to successful CDMO partnerships. As the central coordinator, they align internal stakeholders with external CDMO teams to meet timelines, deliverables, and compliance requirements. They also translate technical, operational, and strategic priorities into well-structured action plans.

Project managers organize meetings, track decisions, and oversee escalation pathways. Throughout the project, they bring cross-functional teams together to maintain momentum, facilitating collaboration between quality, regulatory, operations, and executive leadership. By taking ownership of the project timeline, these managers also mitigate issues before they create significant delays.

Increasingly, CDMO arrangements involve multiple geographies, technologies, or product lines, necessitating sophisticated project management. Integrating workstreams, technology transfers, and reporting keeps complex operations running smoothly.

Implementing KPIs

To maintain development and manufacturing control and ensure regulatory compliance, KPIs must be specific, measurable, and aligned with contractual expectations. Common KPIs include on-time delivery, batch success rates, deviation frequency, out-of-specification (OOS) incidents, and inquiry responsiveness.

Tracking and reviewing these indicators routinely enables sponsors to assess CDMO performance, identify trends, and drive accountability. Additionally, they allow sponsors to benchmark CDMO performance against industry standards and internal expectations.

Additionally, companies commonly use specific performance benchmarks like manufacturing cycle times, product defect rates, and on-time delivery percentages. For instance, expecting cycle times within a 5% variance of the agreed standard, maintaining a defect rate below 1%, or ensuring 98% on-time delivery for clinical or commercial batches.

Companies also measure success by regularly comparing CDMO performance to internal historical data and industry standards. Benchmarking CDMO results against peers or regulatory expectations helps companies identify exceptional performance or areas needing improvement.

Conducting Routine Quality Audits And Inspections

Routine quality audits and inspections verify that the CDMO is complying with GMP standards and sponsor expectations. The sponsor and CDMO’s subject matter experts should collaborate in advance to define each audit’s scope and objectives.

Schedule periodic on-site or virtual audits to review documentation practices, development and manufacturing processes, personnel training, and facility readiness. Regular audits also build personal relationships and strengthen communication between parties. Unannounced audits can address high-risk situations or follow up on unresolved concerns.

Additionally, monitoring batch records and deviations in real time gives companies ongoing insight into operational performance and quality control, enabling rapid corrective actions. Sponsors should collaborate with CDMOs to gain access to digital systems or data portals that allow them to review critical documents and incident reports promptly.

Sponsors and CDMOs must also be prepared for regulatory inspections. Updating documentation, training records, and audit trails demonstrates ongoing adherence to GMP and quality standards.

These audits strengthen collaboration and identify opportunities for improvement. Findings from all audits should be followed by clear corrective and preventive action (CAPA) plans with clearly defined timelines and ownership.

Managing Change Control And Process Improvements

Finally, managing change control and process improvements maintains regulatory alignment and operational consistency. Proposed changes to development or manufacturing processes, analytical methods, or materials undergo a formal change control process agreed upon by the sponsor and the CDMO.

The process includes impact assessments, regulatory reviews, and approval workflows. Sponsors and CDMOs should work jointly to enhance efficiency, quality, or cost-effectiveness while maintaining compliance.

Handling Challenges And Conflict Resolution

The governance framework guides what actions sponsors should take if challenges arise. For example, if the CDMO does not meet its obligations, such as falling behind schedule or failing to comply with regulatory requirements, or if unexpected scientific or technical developments occur. Sponsors should take early warning signs seriously, determine an escalation pathway, and respond to issues quickly and decisively.

Identifying Early Warning Signs Of Issues

Challenges can and will arise in any partnership, but proactively identifying and addressing issues before they escalate mitigates is critical to effectively managing a sponsor-CDMO relationship.

First, sponsors should be on the lookout for early warning signs, including a decline in KPI performance, increased deviation frequency, delayed responses to inquiries, or capacity constraints are common red flags that should not be ignored to avoid risking regulatory compliance.

Tracking deviations, CAPAs, and non-conformances can identify trends that may indicate deeper problems. Pre-established escalation protocols guide sponsors in addressing concerns before they impact timelines.

Resolving Performance Or Compliance Issues

Sponsors should deploy a collaborative, root-cause-oriented approach to create fair solutions if performance or compliance issues emerge. Both parties should transparently review the problem, agree on contributing factors, and develop CAPAs.

The emphasis should be on partnership and problem-solving, not blame. Balancing contractual enforcement with relationship preservation helps avoid unnecessary disruptions.

However, if a CDMO repeatedly fails to meet expectations or respond adequately to CAPAs, sponsors may need to escalate the issue within the governance framework, including executive-level discussions.

Deciding Whether To Change CDMOs

In rare cases, a sponsor may need to change CDMOs. Given technology transfer complexity, cost, and regulatory implications, this is not a simple decision. Sponsors must also consider business continuity, supply chain impact, patient risk, and contractual obligations.

Serious ongoing issues that might call for the move to a new CDMO include chronic failure to meet KPIs, repeated quality issues or deviations, resistance to corrective action, poor communication, or lack of transparency. A breakdown in trust or an inability to align expectations and values also signals that the partnership may no longer be viable.

Sponsors also weigh the risks and costs of switching CDMOs, including potential development timeline delays, regulatory approvals, increased tech transfer and revalidation costs, and product supply disruptions.

A risk-benefit analysis with input from cross-functional stakeholders can determine whether the long-term benefits of changing CDMOs outweigh the short-term challenges.

If a change is necessary, a structured exit plan and well-documented performance history facilitate smoother transitions. Strong governance, communication, and trust are the best defenses against drastic measures.

Expanding And Scaling The CDMO Relationship

When the partnership is successful, biotech or pharma companies often continue with current CDMO partners for further development or manufacturing at next phases, and to develop new therapies in their pipeline.

Evaluating The CDMO For Long-Term Strategic Fit

Sponsors frequently seek a CDMO they can engage for long-term or multiple projects. A strong long-term partner has demonstrated operational excellence and can evolve with the sponsor’s product pipeline and business needs.

Sponsors consider a CDMO’s scale-up and commercial capacity, regulatory track record, technological capabilities, and cultural alignment. Additionally, they evaluate the CDMO’s investment in new technologies, facilities, or service expansions and whether they are prepared to meet global regulatory requirements for new markets. The CDMO’s long-term vision and business plans should also be discussed.

These factors determine whether the CDMO can support future products, new markets, or increasingly complex development and manufacturing demands.

Planning For Portfolio Expansion Or New Projects

Launching a new product often prompts sponsors to reevaluate their CDMO partnerships and decide whether to expand operations with an existing partner or branch out.

First, sponsors should define the new product’s development and manufacturing needs to see if their current CDMO partner can meet these criteria. They should also reevaluate governance structures, capacity planning, and resource allocation to determine whether the CDMO's capacity aligns with internal pipeline growth.

Additionally, sponsors should conduct risk assessments for new projects and define how expansion impacts quality oversight, KPIs, and communication cadence. When negotiating a new project, timelines, technology transfer strategies, documentation requirements, and regulatory expectations should also be addressed. Early collaboration between cross-functional teams ensures a smooth and scalable approach to portfolio growth.

Navigating Contract Renewals Or Transitions

Contract renewals are an opportunity to realign expectations and terms based on past performance and future goals. Sponsors should conduct a thorough performance review before negotiations, evaluating factors such as delivery track record, responsiveness, audit outcomes, and flexibility.

Pricing, service levels, liability terms, intellectual property protections, and change control provisions are among items that should be covered during negotiations. If sponsors consider transiting to a different CDMO, they should prepare a detailed transition plan for knowledge and technical transfer, regulatory filings, and inventory management. Whether renewing or transitioning, a well-managed process preserves continuity and minimizes disruptions to supply and development.

Managing Global Supply Chains For Expansion

Global CDMO partnerships provide specialized manufacturing capabilities, cost advantages, and faster entry into new markets. However, careful coordination is needed to manage production schedules, ensure consistent quality standards, and handle cross-border logistics.

Global operations also entail varying regulatory requirements, customs challenges, and geopolitical risks like trade restrictions or regional instability. Sponsors must work closely with their CDMOs to monitor evolving regulations, maintain up-to-date compliance documentation, and develop contingency plans to address potential disruptions. Regularly reviewing global supply chain performance and risk profiles ensures resilience and responsiveness.

Sponsors with real-time visibility into shipment tracking, temperature control, and inventory movements can quickly resolve any deviations in concert with their CDMO partners. Strong governance, proactive risk management, and continuous communication help global supply chain operations run smoothly even as companies scale.

Conclusion

Effective CDMO management ensures sustained quality, compliance, material and product delivery reliability, and operational efficiency. A robust, collaborative governance framework sets the stage for a mutually beneficial relationship. Ongoing KPI monitoring and routine audits help sponsors quickly respond to issues as they emerge, although sponsors should be careful not to micromanage their partners.

Planning conflict resolution and escalation strategies also maintain a productive partnership. Finally, when sponsors are ready to expand their pipeline, they should reevaluate their relationship with the CDMO to determine if they are fit for future projects. Employing these best practices supports sponsors and CDMOs as they work together to develop safe, effective therapies.

This page is Part 5 in our series on working with CDMOs. For more information on best practices for outsourcing pharmaceutical development, you can visit:

- Outsourcing 101

- Preparing For CDMO Outsourcing

- How To Select The Right CDMO

- CDMO Onboarding And Tech Transfer

Frequently Asked Questions (FAQs)

Below are commonly asked questions on managing a sponsor-CDMO relationship.

1. What are the common challenges in managing a CDMO relationship?

Managing a CDMO often involves navigating communication gaps, misaligned expectations, quality concerns, and differing organizational cultures. If not proactively addressed, these challenges can lead to delays, compliance issues, or breakdowns in trust.

2. How can I monitor the performance of a CDMO throughout the project?

Performance should be monitored using a combination of KPIs, regular status meetings, quality audits, and real-time access to operational data. Continuous oversight ensures that issues are identified early and addressed collaboratively.

3. What KPIs should be tracked when managing a CDMO?

Key KPIs include on-time delivery, batch success rates, deviation and CAPA trends, OOS events, responsiveness to inquiries, and audit performance. These and other metrics help evaluate quality, efficiency, and overall reliability.

4. What role does governance play in managing a CDMO relationship?

Governance provides the structure for oversight, decision-making, and issue resolution. A clear governance framework defines roles, responsibilities, escalation pathways, and meeting cadence, ensuring alignment throughout the engagement.

5. How can I navigate contract negotiations and renewals with a CDMO?

Performance data, evolving business needs, and lessons learned during the partnership should guide negotiations and renewals. Contracts should address pricing, service levels, quality responsibilities, and provisions for scalability or exit.

6. What technologies or tools can assist in managing a CDMO relationship effectively?

Digital platforms for project management, document sharing, and quality tracking can enhance collaboration, transparency, and data-driven decision-making.

7. When should I consider changing my CDMO?

Changing CDMOs is an option that must be given serious consideration. Before deciding, in most cases a full effort to work out challenges with your current CDMO is advisable. However, moving to a new external partner should be considered when persistent quality issues, repeated non-compliance, missed KPIs, or a lack of responsiveness and transparency exist. This decision should be based on carefully evaluating risks, costs, and long-term strategic fit.

8. How can I ensure continuous compliance with regulatory expectations?

Continuous compliance is achieved by strong project management (internally and at the CDMO), conducting routine audits, maintaining up-to-date documentation and training records, monitoring operations in real-time, and fostering a quality culture across both organizations.

9. What is the best way to plan for CDMO relationship expansion?

Planning should include reassessing governance structures, ensuring capacity readiness, aligning expectations, and formalizing updated quality and communication protocols. Reassessing capacity, capabilities, available skilled workers, and timelines is essential. Early engagement and shared risk assessments are key to successful expansion.

About The Author

Elizabeth Mann is a skilled writer with over a decade of experience in content creation, specializing in the life sciences industry. As a writer for Life Science Connect, she develops in-depth content that informs and engages professionals in the pharmaceutical, biotech, and medical device sectors. Her areas of focus include biologic drug production (including cell and gene therapies), clinical trial design and execution, and drug development and manufacturing outsourcing.

EDITORIAL PERSPECTIVES ON CDMO MANAGEMENT

-

Lynn Cinelli's Wake-Up Call: Pharma's Forecasting Makes CDMOs Sick

Lynn Cinelli, VP Global Biologics Supply Chain at Bristol Myers Squibb, has been strategizing on why Pharma is so poor at forecasting demand. "The entities that feel the pressures most may be our CDMOs,” she says. She has a better way to go about it — and it starts with the patient.

-

Pain And Pleasure In Project Management Of CDMOs

Tony Sampognaro of Stoke Therapeutics, says, “We're having to rearrange and bolster the constellation of CDMOs we're working with." The nice thing is, Stoke has a comprehensive extended enterprise model. Nonetheless, an all-outsourced model “can add hidden complexity." Here's how to manage that.

-

Every CDMO Is Perfect Before The Project Starts

Jin-an Jiao, VP, Process and Analytical Development, Synthekine, has worked with CDMOs around the world. "When you talk with them about starting a new project," he says, "everybody's perfect. Everybody's great.” Unfortunately, that can change quickly, and thus the need to confirm "a real commitment to timelines." Part 3 and our final discussion with Jiao ...

-

Your CDMO's Maintenance, From Roof To Floor And Ever More

Facility Maintenance –an all-encompassing descriptor. It starts with taking care of an internal ecosphere - everything from roof to floor. It also includes an exosphere – the real estate the facilities sit on, the business parks where they are located, and the communities they reside within. When you are outsourcing, it makes you a part of it all as well. How much do you know about this area of your CDMO’s existence?

-

Who Handles Maintenance At Your CDMO? You Should Know

Computerized Maintenance Management Systems (CMMS); Integrated Facilities Management (IFM); Mechanical / Electrical Systems (M&E); and pest control (!) ... who handles maintenance at your CDMO? Here's what you should know from someone who has been doing it for decades.

EXPERT INSIGHTS ON CDMO MANAGEMENT

-

To Enhance Biotech Investments, Involve CDMOs Early In CMC Decisions

In Part 1, we introduced the critical link between CMC and prospective investors and/or licensees. Here we conclude with suggestions for how CDMOs can lend expertise early in discovery/development to improve the probability of securing investment or license for their clients.

-

8 Actions To Redefine Sponsor–CDMO Relationships

When viewing a CDMO as merely a service provider, interactions are often limited to completing tasks. This mindset can stifle innovation and problem-solving.

-

Lethal Combat With Your CDMO

In this part two, Outsourced Pharma Advisory Board member Shawn Eisenberg tells us that in challenging times, pursuing combat with your CDMO ends up injurious to both parties. He believes the ways of resolving conflicts "are probably as varied as the ways of getting into them."

-

When Conflict Arises With Your CDMO

Outsourced Pharma Advisory Board Member Sean Eisenberg details how to handle and overcome conflicts between drug sponsors and CDMOs. This is part one of a two-part dissertation on a subject that, if you outsource, will certainly arise ... if it hasn't already.

-

7 Focus Areas To Establish A Win-Win Relationship With Your CDMO

Working with a CDMO doesn’t always go as planned. This article outlines the factors that will impact project success and set up a “win-win” relationship.