Preparing For CDMO Outsourcing: Key Steps For Successful Biopharma Collaboration

A successful outsourcing partnership doesn’t happen by chance. Before beginning the CDMO selection process, companies must internally align and develop careful strategies to ensure clear communication, risk mitigation, and mutually beneficial outcomes.

This is Part 2 in our series on working with CDMOs. (To start at the beginning, visit our Outsourcing 101 page.) This guide shares best practices for preparing to work with a CDMO, including:

- Laying The Groundwork For A Successful CDMO Partnership

- Defining Internal Requirements Before Searching For A CDMO

- Preparing To Engage With The CDMO Market

- Frequently Asked Questions (FAQs)

Laying The Groundwork For A Successful CDMO Partnership

Preparing for a CDMO partnership begins with internal assessments to determine a company’s strategic and operational objectives, facilitate internal readiness, create a budget, and develop a risk mitigation framework.

Determining Strategic And Operational Objectives

Defining strategic and operational objectives begins with assessing internal capabilities to identify critical gaps that a CDMO would fill, such as technical expertise, infrastructure, speed to market, or regulatory navigation. These insights shape the selection process and set the foundation for productive collaboration.

Next, companies should consider how their CDMO engagement goals align with their broader corporate strategy. For example, leading priorities may be accelerating development timelines, reducing overhead and capital expenditures, or accessing niche technologies and specialized talent. Regardless of the internal motivation, the rationale for outsourcing must be explicitly defined and agreed upon in advance to ensure the CDMO supports rather than complicates the company’s path to market and commercial success.

Furthermore, companies must determine the CDMO’s scope of work, such as process development, clinical trial material supply, or commercial-scale manufacturing. Some sponsors, particularly startups, may need end-to-end services encompassing the entire development lifecycle, while others need to fill a specific gap. Clarifying scope defines all parties' expectations, timelines, and necessary resource commitments.

During the planning phase, companies should also decide whether they prefer a local, regional, or global CDMO partner. The CDMO’s location can affect regulatory alignment, logistics, and communication. For instance, manufacturing in a specific region may support local market entry or import/export regulation compliance.

Facilitating Internal Alignment And Readiness

Strong internal coordination is key to a successful CDMO partnership. Companies should form a cross-functional team that includes R&D, chemistry, manufacturing, and controls (CMC), regulatory affairs, quality assurance, supply chain, finance/procurement, and legal. This team evaluates CDMO capabilities, manages project execution, and maintains compliance.

After forming the team, their roles, responsibilities, and decision-making authority should be clearly defined, including assigning an internal project manager for each outsourced product or service.

Each function should take ownership of specific areas with streamlined approvals and issue escalation pathways. Without this internal clarity, delays and miscommunications can undermine outsourcing efforts.

Companies should establish key metrics to objectively evaluate the CDMO relationship once it is underway. Benchmarks commonly include project timelines, quality standards, regulatory milestones, cost performance, and relationship management.

Creating A Budget

Determining a realistic budget is crucial to preparing to work with a CDMO. An effective budget strategy encompasses the full financial footprint of outsourced development and manufacturing activities.

Direct costs, such as service fees for process development, clinical supply production, and commercial manufacturing, are relatively straightforward to estimate. However, hidden expenses can derail budgets. For example, companies should consider expenses associated with technology transfer, regulatory filings, CDMO oversight, project management, change orders, and quality audits. Failing to plan for these expenditures can lead to budget overruns and strained partnerships.

Seasoned sponsors can leverage their previous outsourcing experience to plan their next budget. Younger companies or startups, however, often rely on market intelligence gained through RFPs and informal discussions with multiple CDMOs, as well as hiring experienced consultants.

This research reveals typical cost structures, service pricing and business models, and potential variability based on project complexity, timeline demands, and regulatory requirements. Early, exploratory conversations can provide invaluable insights into creating an informed, defensible budget.

Finally, careful budget planning enables internal teams to prioritize their needs, define trade-offs, and discover when and where to employ cost-containment strategies.

Developing A Risk Mitigation Framework

Risk management is another cornerstone of an effective outsourcing relationship. A structured risk management framework identifies, categorizes, and mitigates risks from early development through commercial launch. This proactive approach reduces disruptions and preserves timeline and budget integrity by considering:

- Financial risks like cost increases, unexpected change orders, or currency fluctuations. Additionally, many companies need continuous funding as the project matures.

- Operational risks include tech transfer delays, capacity constraints, raw material shortages, quality failures, or catastrophic events at CDMO facilities.

- Regulatory risks, including failure to comply with current good manufacturing practices (cGMP), data integrity standards, or evolving regional regulatory expectations.

The team should consider each risk area's likelihood, impact, and existing controls to define appropriate mitigation strategies, such as dual sourcing, buffer capacity, contractual safeguards, or regular risk reviews. Early structured risk planning positions sponsors to swiftly and confidently respond to challenges as they arise.

Defining Internal Requirements Before Searching For A CDMO

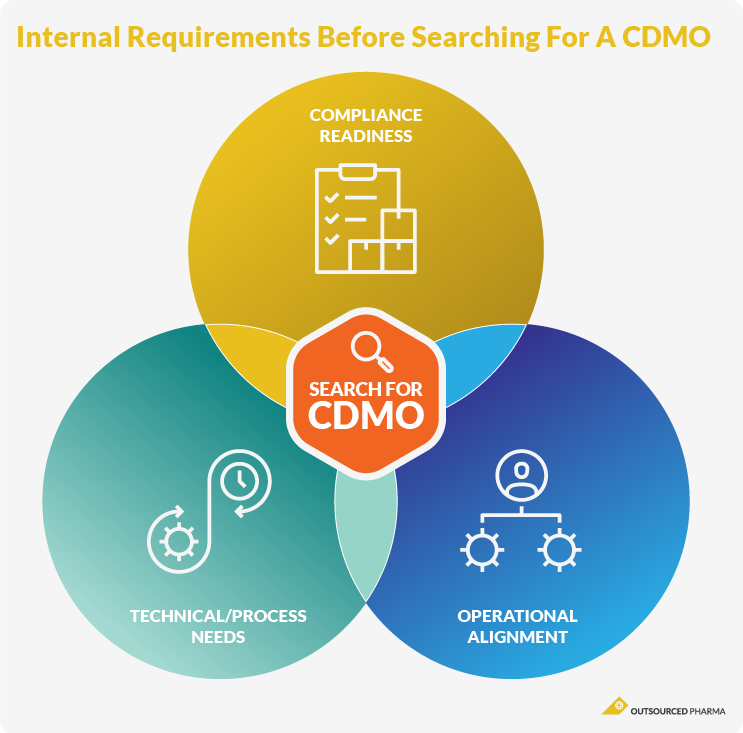

Before beginning vendor selection, sponsors should consider their specific program needs, internal capabilities, company culture, and regulatory compliance needs to avoid costly scope changes or delays.

Technical And Process Considerations

When preparing to work with a CDMO, sponsors must precisely define their technical and process requirements for each project or program, including technologies, process development goals, and manufacturing capabilities.

For instance, they should consider the specific modalities or platforms involved, such as biologics, small molecules, or cell and gene therapies. They should also weigh the development stage and phase-appropriate activites, and necessary specialized capabilities such as aseptic processing, high-containment environments, or lyophilization.

Scale and scalability requirements need to be assessed. While early-stage clinical manufacturing typically needs speed and flexibility, commercial-scale production requires robust processes, regulatory compliance, and capacity assurance. Planning teams should align internal expectations with the regulatory guidelines for each development phase and product type.

Sponsors must identify critical process parameters and which process variables are essential for product quality, yield, or stability, and define mitigation steps like robustness testing or technology upgrades.

Cultural And Operational Alignment

Creating a successful CDMO partnership also depends on cultural and operational compatibility as well as technical capabilities. Sponsors should define clear expectations regarding communication, project management, and responsiveness to set the tone for collaboration and cooperation.

For example, sponsors should decide whether their project needs a highly structured, milestone-driven approach or an adaptive collaboration with real-time problem-solving. Some programs thrive under strict governance models with formal reporting and escalation paths, while others require a flexible, fast-moving environment.

Additionally, sponsors should determine the flexibility they need from the CDMO, particularly for scheduling, batch prioritization, or change management. A quickly evolving program needs a CDMO that can accommodate changes without adding excessive time or costs.

Finally, sponsors should create guidelines for transparency, communication cadence, and data-sharing protocols by defining preferred platforms, reporting formats, meeting cadence, and handling procedures for sensitive or proprietary information. Cultural alignment fosters trust, prevents miscommunication, and ensures both sides work from the same assumptions.

Quality And Regulatory Compliance Readiness

Internal teams should also determine the quality and regulatory expectations governing the outsourced project, such as cGMP, ICH guidelines, or regional regulations.

First, internal regulatory and quality teams should be created to assess a prospective CDMO’s compliance system, audit capabilities, and historical performance. Sponsors should establish this infrastructure to overcome common hurdles like inspections, deviations, or product recalls.

Next, sponsors should develop a structured, well-documented approach for tech transfer. Process documentation, analytical methods, specifications, and historical data are established during the planning phase to ensure the CDMO can accurately and efficiently reproduce processes.

Finally, sponsors should consider the specific regulatory frameworks governing the project and how the CDMO's experience, inspection history, and compliance framework could support or complicate market-specific submissions and approvals. Determining these expectations enhances vendor selection and minimizes regulatory surprises during production.

Preparing To Engage With The CDMO Market

Before companies begin the CDMO selection process, they should conduct market research, establish an initial outreach plan, evaluate internal readiness, and strategize change management.

Conducting Market Research

Comprehensive market research gives cross-functional teams vital information on the CDMO market, services, and industry benchmarks for timelines, costs, and capabilities.

Research sources include internal colleagues with prior outsourcing experience, recommendations from industry peers, findings from conferences or partnering events, and third-party data platforms. For example, Outsourced Pharma’s CDMO Leadership Awards leverage industry feedback to help companies navigate the CDMO market. These insights help internal teams consider size, specialization, and geographic reach when selecting partners.

Market research helps teams determine whether a large, integrated CDMO or a smaller, highly specialized partner could better meet their goals without prematurely locking into selection decisions.

Establishing An Initial Outreach Plan

A well-coordinated outreach plan provides consistent communication and keeps strategic objectives in focus throughout the early engagement process.

First companies create a draft RFP template outlining project scope, technical requirements, regulatory expectations, timelines, and evaluation criteria. Additionally, the template should describe deliverables, quality standards, logistics, and commercial terms.

The RFP template evaluates a CDMO’s capabilities, experience, and risk management. It may evolve during the CDMO evaluation process, but early planning ensures that comparable data is collected and evaluated.

For example, internal teams decide what information to request during the exploratory stage, including general capabilities, experience with relevant product classes or technologies, and regulatory history.

Likewise, a structured internal review process for early interactions and findings keeps the team on track. Standardized templates or comparison tools, such as intake forms or scorecards, evaluate each engagement consistently and transparently.

Furthermore, roles and responsibilities must be defined for leading outreach, managing communications, and sharing findings. These strategies create a disciplined, informed approach to CDMO engagement.

Strategizing Change Management And Internal Communication

Engaging a CDMO partner is more than just a technical or operational decision. Working with a CDMO represents a significant organizational shift that must be intentionally managed for successful outcomes.

Outsourcing may raise internal concerns about control, accountability, or job security, particularly for inexperienced teams. Preparing for this paradigm shift requires clear, consistent internal communication and strong support from leadership.

Early executive buy-in establishes outsourcing as a strategic priority. Leadership support also gives cross-functional teams confidence and positions their efforts in the company’s broader business goals.

Additionally, companies should manage expectations across key functions like R&D, regulatory, and supply chain management. The CDMO partnership will affect these departments' workflows, and early communication around expected changes and available support facilitates a smoother transition.

Finally, companies should identify and address internal resistance to outsourcing. Resistance may arise from uncertainty, prior negative experiences, or fear of losing influence. By acknowledging these concerns, creating forums for open discussion, and involving affected teams in planning and decision-making, organizations can reduce friction and build a shared commitment to success.

Conclusion

Preparing to engage a CDMO is a detailed, intentional process that should leverage cross-functional teams and foster a culture of open communication. Determining internal readiness, defining technical and quality needs, conducting market research, and creating RFPs contribute to a smoother selection process. Empowering internal teams alleviates anxieties and encourages collaboration.

The next page in this series details How to Select the Right CDMO. The series also includes Outsourcing 101, CDMO Onboarding And Tech Transfer, and How To Manage CDMOs.

Frequently Asked Questions (FAQs)

Below are frequently asked questions on preparing to work with a CDMO.

1. Why is internal alignment important when preparing to work with a CDMO?

Internal alignment ensures that all stakeholders share a common understanding of project goals, priorities, and requirements before engaging with a CDMO. Organizations risk miscommunication, unclear expectations, and delays that can undermine the partnership without alignment. A unified internal position supports more effective external interactions and streamlines the CDMO selection and onboarding process.

2. What teams should be involved in the CDMO preparation process?

A cross-functional team should guide CDMO preparation and engagement. This typically includes representatives from R&D, CMC, regulatory affairs, quality assurance, supply chain, finance or procurement, and legal. Each function is key in defining requirements, managing risk, and ensuring the CDMO relationship aligns with organizational needs and compliance standards.

3. What budget considerations should I consider during the preparation phase?

Sponsors should build a comprehensive budget that includes direct service fees and hidden costs such as technology transfer, regulatory submissions, project oversight, and quality audits. Accurate budgeting requires experience or insights gained from CDMO conversations and RFP responses. Planning for the full financial scope helps avoid surprises and supports more realistic decision-making.

4. Why is change management critical in CDMO preparation?

Engaging a CDMO often represents a significant shift in internal teams' operations. Change management helps prepare stakeholders for new workflows, external collaboration, and evolving roles. By managing expectations, securing leadership support, and addressing concerns early, sponsors can reduce resistance, build buy-in, and facilitate a smoother transition into the outsourced model.

5. How do I determine the right scope of work for a CDMO?

Defining the scope of work requires a clear understanding of your internal capabilities and the gaps a CDMO needs to fill. Consider whether support is required for process development, clinical supply, commercial manufacturing, or full-service lifecycle management. Align this scope with your development phase, strategic goals, and available internal resources.

6. What role does geographic location play in CDMO selection?

Geographic location can affect logistics, communication, regulatory alignment, and market access. For some projects, proximity enables faster turnaround and easier oversight, while for others, locating a CDMO in a target commercial region may support strategic market entry or reduce regulatory complexity.

7. What should be included in early CDMO outreach?

Initial outreach should focus on gathering high-level information about a CDMO’s technical capabilities, experience with similar products, capacity, and regulatory track record. This helps gauge potential fit before investing in a detailed RFP or evaluation process. Consistent data collection tools and scorecards can support internal comparison and prioritization.

8. How do I communicate technical requirements clearly to a CDMO?

A: Sponsors should document and share detailed technical needs, including critical process parameters, scalability requirements, and known risks. Preparing structured technology transfer packages and robust documentation allows CDMOs to replicate processes accurately and reduce the risk of delays or rework.

9. Why must internal readiness be assessed before the selection phase?

A: Internal readiness ensures that all functions involved in the CDMO relationship are aligned, that selection criteria are clearly defined, and that responsibilities for evaluation and decision-making are assigned. This preparation enables a smoother transition into formal CDMO assessment and ensures a disciplined, efficient selection process.

10. How can I mitigate risks before outsourcing to a CDMO?

Developing a structured risk mitigation framework early in the process allows sponsors to anticipate financial, operational, and regulatory risks. Identifying these risks and establishing contingency plans, such as backup suppliers, flexible contracts, or predefined escalation paths, helps ensure project continuity.

About The Author

Elizabeth Mann is a skilled writer with over a decade of experience in content creation, specializing in the life sciences industry. As a writer for Life Science Connect, she develops in-depth content that informs and engages professionals in the pharmaceutical, biotech, and medical device sectors. Her areas of focus include biologic drug production (including cell and gene therapies), clinical trial design and execution, and drug development and manufacturing outsourcing.

EDITORIAL PERSPECTIVES ON PREPARING FOR CDMO OUTSOURCING

-

Stop Hiring Now! Stay Virtual

Robert Discordia, Co-Founder, President and CEO, EQUULUS Therapeutics, knows that to advance early-stage development assets most economically, biotechs should (a) stay within their virtual model, and (b) base that outsourcing strategy on initial business objectives. Here are his dos and don'ts.

-

Biotechs Should Go With An Uber Not A Limo

Bob Discordia had been in stealth mode for a while. When he finally emerged, Chief Editor Louis Garguilo knew his newco would include a precise model of outsourcing. The reveal came earlier this year with the announcement he had founded EQUULUS Therapeutics, a neuroscience biotech. So how will Discordia outsource? He'll take an Uber ... and advises you do the same.

-

Go Ahead, Outsource Your Entire Biotech

Persephoni BioPartners CEO Hilary Schultz has created a business model that may propel “externalization” to an ultimate implementation: The formation of a biotech by outsourcing the entire organization, which then outsources to advance an asset. Schultz describes Persephoni as a venture studio. Chief Editor Louis Garguilo investigates further ...

-

When Should You Select Your Supply Partner?

In this part two, James Doherty, President and Chief Development Officer, provides readers with a window into the contracting strategy of Acumen Pharmaceuticals, a biotech developing a novel therapeutic for the treatment of Alzheimer’s disease (AD). Acumen has announced it entered a CDMO contract for both clinical and any future commercial supply.

-

If The CDMO Shoe Fits, Wear It Now

Acumen Pharmaceuticals, a clinical-stage biopharmaceutical developing a novel therapeutic for the treatment of Alzheimer’s, selected its manufacturing partner early on, and told the world about it. Chief Editor Louis Garguilo asked the chief development officer about that strategy.

EXPERT INSIGHTS ON PREPARING FOR CDMO OUTSOURCING

-

Exploring The Market For Closed-Loop Cell Therapy Production

The second part of a discussion on closed-loop systems explores the CDMO and equipment landscape for scaling automated closed loop cell therapy manufacturing systems.

-

What CDMOs Wish Biotechs Knew Before Submitting An RFP

This author has worked with CDMOs across different programs and therapeutic modalities. Each experience reinforced the same lesson: a strong RFP can make or break a partnership.

-

Small Molecule CDMOs: Recent Consolidation And Expansion Developments

As the small molecule CDMO landscape expands, it is still fragmented, driving both M&A and big capital projects to get ahead.

-

Are CDMO Partnerships The Answer To Manufacturing Capacity Issues?

The current manufacturing strain is exacerbated by factors such as the intensity of scaling up fill-finish and specialized manufacture of drug delivery devices. How can partnering with a CDMO help?

-

Which Of These 6 Outsourcing Models Best Suits Your Program?

Outsourcing used to be a cost-cutting exercise. Now drug developers use it to add expertise and manufacturing efficiencies to their production teams.