INSIGHTS ON DRUG DEVELOPMENT

-

Redefining OSD Development Through Foresight And Innovation

From early formulation challenges to scale-up and commercial readiness, proactive planning and integrated capabilities help teams anticipate risks, accelerate decision-making, and maintain momentum across development.

-

FIH: Reach Milestones Sooner With A Technology-Driven Approach

Accelerate your path to IND and FiH with AI-driven design, advanced cell line engineering, and intensified processes delivering high titers in 9–14 months.

-

CHO K1 Cell Culture Process Intensification For Enhanced Production Of IgG mAbs

Discover how our optimized CHO K1 cell lines achieved up to an 80% increase in titer while maintaining product quality through molecule-specific process development strategies.

-

The Science Of Cell Line Development For Biologics

Selecting and engineering the right cell line is not simply a technical milestone; it is a strategic decision that shapes cost of goods, development timelines, and the overall probability of success.

-

Right From The Start: Smarter Developability For Stronger Formulations2/4/2026

Early developability assessment integrates manufacturability, QbD, flexible formulations, and CDMO support to cut risk, speed development, and enable scalable, robust drugs.

-

Development Of A Non-Standard Protein Therapeutic2/4/2026

Discover how a tailored development approach transformed a complex therapeutic protein into a candidate ready for early-stage clinical trials.

-

Viral Clearance Strategies For Monoclonal Antibodies And Proteins1/30/2026

Guidance on designing viral clearance studies using regulatory-aligned, risk‑based strategies, optimized assays, and real case examples for safe, efficient biologics development.

-

Oligonucleotide Purification And Synthesis1/27/2026

Examine how a 21‑mer oligo was synthesized and purified through systematic resin screening, method optimization, and successful scale‑up to build reliable, high‑purity chromatography workflows.

DRUG DEVELOPMENT SOLUTIONS

-

Integrated human ADME studies streamline the process from 14C synthesis to clinical conduct and final reporting to accelerate your drug development program.

-

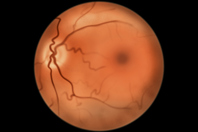

With our specialized support, you can be confident that your ophthalmic drug will not only meet regulatory standards but also address unmet medical needs in the most expedited manner possible.

-

We are an established leader in advancing vaccines from preclinical development to commercial supply across multiple modalities.

-

Learn how a bioanalytical testing partner with comprehensive solutions and unwavering commitment to quality can help you bring safe and effective drugs to market with confidence.

-

Improve productivity and cell growth in fed-batch cultures by supplementing the cell culture medium to boost nutrients depleted during culture. HyClone™ Cell Boost™ 2 Supplement provides nutrients such as amino acids and glucose that are suitable for research and bioprocessing applications.