The Most Difficult Outsourcing Tasks

By Louis Garguilo, Chief Editor, Outsourced Pharma

How do you select your CDMOs?

After 31 years of outsourcing from various positions at Pfizer, Francis Dumont offers what sounds like a noncommittal reply, but actually is one infused with high-brow wisdom.

“My basic answer is it depends,” he says.

The fortunate circumstances of his career, as he likes to say, in which he’s been involved in a variety of sourcing efforts, has helped him derive a systematic flexibility for drug development and manufacturing outsourcing activities.

For the few key technologies Pfizer decided not to invest in internally, Dumont’s team had a relatively small number of select, external partners with whom they’d arrived at “overarching terms.”

That short list – and some of those terms – weren’t always fully copacetic with “procurement philosophies,” mostly, says Dumont, “because it could appear as sole-sourced or lacking competitive bidding.”

However, he says, these long-term relationships work when “the track record along with sufficient benchmarking substantiate that a reasonable cost is being paid for consistent high quality, timely, and reliable services at a certain provider.”

On the other end of the spectrum – in those areas Pfizer hadn’t previously gone out to the outsourcing market for materials or services – selecting partners was approached much differently.

When It’s The First Time

Starting from scratch, as it were, Dumont and team would assemble a cohort of internal subject matter experts to start the selection process.

“This could be a six-month process,” he explains. “There are many ways you can put together and narrow down lists of potential external partners.”

At the highest level of this initiating exercise, he says, are the non-negotiables.

These are usually a few must-haves to focus on, depending on program and stage, but often include quality, timing, and for later stages, regulatory experience in targeted patient markets.

He advises “quickly screening out for those real non-negotiables,” whatever they may be, when looking for new CDMOs.

“From there, a lot comes down to having well designed RFPs, either using an example or an actual program” that CDMOs can clearly understand and fully respond to.

The team of internal SMEs then weigh in on the veracity and validity of those CDMO responses.

This collective team employs a scoring approach. “It’s a robust sourcing process, and procurement is involved, but there is as much push and leadership from the technical lines as there is from procurement.”

Chicken Or Egg?

I ask Dumont if there are times when the external options are so good it leads a Big Pharma to decide it doesn’t need to invest internally in a certain area. Or is it always an initial identification of core capacities, and then deciding to outsource the rest?

“I debated that very topic for probably my last 20 years at Pfizer,” he replies.

He has led large, external projects progressing “exceptionally well,” but “the internal question remains: ‘Are we still going to be doing this five years from now?’”

“If the answer is affirmative, is someone in our organization going to say, ‘Then our facilities can rapidly gear up to do that’?”

So in this case it's outsource first, and potentially bring it home subsequently.

In other cases there can be “more profound impacts” on insourcing/outsourcing decisions, such as technology breakthroughs, market gyrations ... even a pandemic.

“People saw our CEO shaking hands with BioNTech’s before any detailed financial negotiations or other decisions were taken,” says Dumont. “Granted, we had an ongoing collaboration on developing mRNA flu vaccines, but the outside world only saw that Pfizer quickly invested in its own facility to provide COVID vaccine access to the world. However, keep in mind there was a lot of parallel work done to explore all potential scenarios to support this program.

“Our CEO put a billion dollars aside and says we're betting on this, we are going to build our own facilities.”

And so what CDMO to select, as well as when to outsource and when not to … depends. On a whole lot.

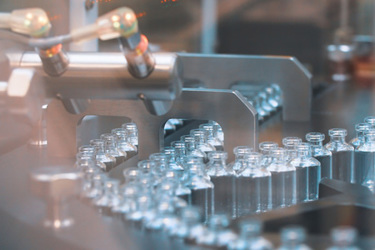

Sterile Finish Most Difficult

Changing gears, when prompted Dumont says the most difficult component of drug development and outsourcing that he has directly supported is sterile drug product.

While there are many players in the industry, he says there are few with “true research and development expertise on sterile-dosage-form, those who can then make clinical stage material, and effectively do internal transfers to their own sterile fill finish commercial facilities.

Coupling that with “ever-changing regulatory expectations” makes sterile dosage a challenging section of our industry. He particularly – if not fondly – recalls the advent of the EU Clinical Trial Directive in 2001 that “kind of kicked things off.”

For companies running global clinical trials, this required changes.

“Suddenly, we needed to host EU-focused inspections at our internal and external pilot scale facilities, and work with QPs to sign off on products.

“That was a huge awakening, as there were discrepancies, many technically nuanced, between US clinical-stage, sterile-fill-finish expectations versus the EU. Some of these could be addressed procedurally, whereas some required facility changes and upgrades.

“We collectively rose to the occasion, but it was definitely a trying and learning experience for our industry.”

Today, understanding the quality management systems that sterile fill finished facilities have in place is critical.

“Moving completely away from manual, hands-on operations to truly automated systems was and continues to be a huge challenge.

“Having the right people that understand the regulations, and then see eye-to-eye with both the contract manufacturers and the sponsor’s quality organizations, is by far the most difficult area I have been directly involved in.”

A final thought:

“I certainly don’t want to undervalue the current state of the CDMO market and sterile fill finish, but, for example, there are many aging facilities that people are trying to bring up to speed instead of building out from the ground up with current expectations in mind. That is complex. It's a huge ask. In either scenario, there is a lot of investment needed.

“In my early days of working in sterile fill finish, I was puzzled why there weren't more robust vendors in the space. I thought, 'Someday I’ll run my own sterile fill finish facility.' I don't think that way anymore. Best to leave it to the true experts.”