Tips For Choosing The Right CMO For Your New Nanotech Drug Delivery System

By Barbara Berglund, CMC Turnkey Solutions

You are thrilled to hear your manufacturing technology group has finished designing the process for your new product in the nanotechnology space. The process is stable and reproducible at a pilot scale. The toxicology studies are in, and your clinical trials are getting started with terrific promise. You are on the cutting edge of the next generation of drug products. This means success not only for your organization, but for the future of healthcare.

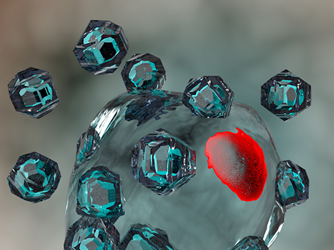

Nanotechnology offers an opportunity to target organs and specific types of cancer and immune disorders. There are biological hurdles to overcome in getting the treatment delivered effectively to the organ, requiring the drugs to be manufactured using complex processes, such as microencapsulation, diafiltration, working with organic solvents, and handling DNA or RNA. Without unique delivery systems, the human immune response would immediately break down these drugs, rendering them useless at the target organ. Thus, the drugs are encapsulated so they can be carried through the blood to the site of disease. From a drug manufacturing point of view, the aseptic handling of some components is not straightforward; sometimes specialized, dedicated work spaces need to be designed, and specialized equipment is essential to the process.

The hurdle you now must jump is getting this product manufactured in a GMP CMO. As you begin your search for your aseptic manufacturing partner, you find the technological needs for nanotechnology are met with questions and concerns; they do not have the right space, the right equipment, or the right facilities for processing these unique drug delivery systems. It is difficult to be the pioneer seeking a partner who wants the opportunity to be on the cutting edge of new technology — and to participate in the future of medicinal chemistry.

Logic may tell you any organization would want to make a name for itself and be viewed as that pioneer and to have an interest in the future. However, this is not typically the case. Nothing pleases a CMO more than a client coming to them with a simple fill-finish site transfer which fits neatly into their wheelhouse. Offer to use their existing components, filling equipment, change parts, known suppliers, and packaging equipment, and they welcome you. However, seeking facility change and accommodation, seeking to install specialized equipment, and seeking to provide unique instructions for handling active ingredients may be a hard sell.

How To Assess The Need For And Encourage Change And Innovation

A negotiation with the CMO with a focus on the future is a solid tactic. When considering how to approach this kind of negotiation, it is critical to understand whether the CMO facility itself can be designed for your process; even more important is the in-house expertise to handle day-to-day needs for your product and process. What infrastructure do they need to implement? This is an end-to-end view: your substance is received at the CMO; it is examined, sampled, stored, and generally handled; it is tested; it is prepared for formulation, which may require special handling; it is formulated in specific buffers to maintain activity; it is then manufactured, which may require sophisticated equipment; and then it is filled, perhaps into non-standard container closure systems depending on stability and reactivity. There may be a need to increase their engineering, operations, and laboratory staff to support your product.

To enable just the product path, the facility needs to accommodate your process, building in the right systems. If your process uses solvent evaporation for microencapsulation, venting systems and environmental safety need to be incorporated and the right monitoring tools and calibration programs in place. Handling DNA and RNA substances is specialized, requiring homogenizing equipment and specific cleaning to remove RNases and DNases which render the product inactive. The process itself may require complex diafiltration or ultrafiltration setups which need to be conducted in an aseptic environment. Then, there is the training of operators and laboratory technicians and keeping them trained as they work on traditional products and processes as usual.

In addition, there are the quality and regulatory components. When a process issue arises during manufacturing, how will the quality of the process be assessed? The quality group at the CMO needs to be able to act appropriately in the initial assessment as you and your own quality are brought into a conversation. You don’t want to face either an over- or an under-reaction. A traditional CMO understands the risk associated with sterilizing filter failure but may not understand the impact of a diafiltration malfunction. Also, while product testing occurs, an unexpected result may require expertise in specialized testing and understanding the boundaries of procedure validation. From a regulatory point of view, an understanding of the facility and operations is critical to your own agency submissions. The CMO may view a gap in having the technology in place as a regulatory risk to their organization.

Knowing this, your approach to a CMO partnership needs to be inclusive and understanding of the level of change which would be needed. Therefore, it is valuable to do your own research into the CMO’s current capabilities, to help build bridges between what they can do and what they need to do. Further, a view of how this would enhance their bottom line is essential, including considering a marketing partnership to help them gain partners with similar needs. It can only enhance the quality outlook for your own product if your CMO gains expertise in their manufacturing space. Further partnership opportunities may be considered, such as contractual commitments, a pipeline of similar products, and future opportunity.

In the end, it is challenging to encourage a CMO to enter into a new technological space. Building infrastructure is expensive, and there is quality and regulatory risk to overcome. However, it is essential to continue the build toward leadership in medical technology so novel drug therapies can be made available for use. With current standard manufacturing practices, medicine cannot advance to where it needs to be for effective therapy.

About The Author:

Barbara Berglund is COO of CMC Turnkey Solutions, where she applies over 20 years of experience in finished pharmaceutical, API, and medical device manufacturing. In particular, she has direct experience with quality assurance and manufacturing of commercial and clinical trial sterile liquid and lyophilized parenterals, microencapsulated products, intravitreal products, suspensions, and solid dosage forms. She has held strategic leadership positions in quality assurance, quality control, sterile manufacturing, and project management and has a particular interest in technical transfers both of processes and analytical procedures.

Barbara Berglund is COO of CMC Turnkey Solutions, where she applies over 20 years of experience in finished pharmaceutical, API, and medical device manufacturing. In particular, she has direct experience with quality assurance and manufacturing of commercial and clinical trial sterile liquid and lyophilized parenterals, microencapsulated products, intravitreal products, suspensions, and solid dosage forms. She has held strategic leadership positions in quality assurance, quality control, sterile manufacturing, and project management and has a particular interest in technical transfers both of processes and analytical procedures.

Berglund has an undergraduate degree in chemistry and postgraduate degrees in chemistry and pharmacological and physiological science. She received her PMI PMP (Project Management Institute Project Management Professional) certification in 2007 and her ASQ CQA (American Society for Quality Certified Quality Auditor) and ASQ CMQ/OE (Certified Manager of Quality/Organizational Excellence) certifications in 2015.