Establishing A Critical Supply Chain For Autologous Cell And Gene Therapies

By Carla Reed, president, New Creed LLC

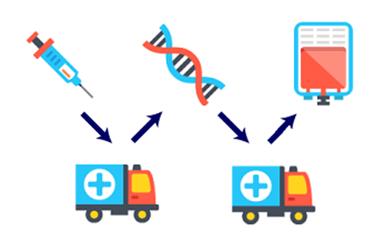

With the recent breakthroughs in cell and gene therapy, there is increased emphasis on the design and implementation of different supply chain models to support the movement of materials and drug product across the chain of care. Unlike more traditional supply chains, many of these therapies have unpredictable sources and manufacturing and infusion locations. The most extreme example is loosely referred to as the “vein-to-vein” supply chain — particularly for autologous therapies.

Vein-To-Vein Supply Chain

The collection, transportation, and storage of blood includes many participants across a variety of global locations. This is relatively mature, as blood donation and transfusion are core activities in clinical and medical environments. What has created a different level of complexity is the increasing use of autologous blood products in the development of a variety of "elixirs of life.” In this case, the critical element includes the chain of identity, with links that collect, transport, cleanse, process, and transform the blood from a single patient. The result — one batch that can only be used by a single individual — is complex and expensive!

From identification of patients who might be candidates for these specialized therapies to delivery of the first shipment of drug product, many process steps need to be understood and planned for. In many cases the personnel engaged in the planning and execution of these shipments are not familiar with the intricacies.

Creating A Digital Data Trail To Retain Item Integrity

The initiation point for this critical chain is the clinical location where a patient provides the starting ingredient — their own blood! In many cases, the patients are in a fragile physical state and the scheduling of the blood extraction needs to be coordinated with clinical personnel. This process can be demanding on the patient, and the integrity and cell count of the source material is critical for the development and yield of the drug product.

As such, the process steps and timing need to be well defined, with no room for error. A series of sequential activities should be included in shipment planning:

- Obtaining the starting materials

- Date and time for patient donation — extraction and processing of blood to create the leukapheresis (the removal of blood plasma from the body by the withdrawal of blood, its separation into plasma and cells, and the reintroduction of the cells, used especially to remove antibodies in treating autoimmune diseases)

- Transportation scheduling, including delivery of temperature-controlled packaging and data loggers

- Labelling requirements for special handling and temperature control

- Packaging and shipment of the primary drug substance (apheresis) — to be maintained at a specific temperature range from extraction to receipt at the processing/production location

- Data logging and time and temperature tracking, during transportation and on receipt of the shipment

- Schedule monitoring to ensure no excursions from the time and temperature range

- Quality control on receipt of the apheresis (schedule personnel for the QA process)

- Delivering the drug product for patient infusion

- Scheduling the patient for infusion (In many cases this requires additional chemotherapy prior to infusion and should be coordinated with the clinical site in the chain of care.)

- Shipment planning and risk assessment

- Packaging review and identification of special handling requirements

- Scheduling shipment pickup and delivery to include packaging components and data loggers (In many cases the shipments are in cryopreservation and require special packaging and material handling equipment.)

- Packaging, labelling, and shipment to the receipt location at the point of care

- Communication with clinical personnel to ensure safe receipt and product inspection (QA process according to agreed-upon SOP)

- Shipment tracking — monitoring and control

- Receipt at the clinical site — QA inspection and stored in appropriate location

Each of these process steps should be defined in a detailed process overview with data inputs and outputs to enable supply process visibility, intervention in the event of a delay or disruption, and confirmation of secure delivery and receipt of the apheresis and drug product. .

Risk Assessment Is Critical — Plan, Adjust As Necessary, And Monitor!

With all critical supply chains, it is imperative to leave nothing to chance. The planning process should include a detailed review of all participants, process steps, data capture, and control as well as check and choke points across the supply chain. Transportation providers should be included in this risk assessment. Factors for inclusion include, but are not limited to:

- regulatory requirements — customs and border control if applicable

- transshipment points across the chain of custody

- changes in mode of transportation (due to potential environmental hazards)

- weather hazards (differences in shipment and receipt locations)

- availability of receiving resources — personnel and material handling

- inspection and the QA process — evaluation of excursion data from time and temperature loggers.

Digital Data — Exception Management And Remediation

Both the apheresis and the final drug product require stringent control across the chain of custody, ensuring the integrity of the chain of identify. In addition to identification of each key process step across the links in the extended supply chain, it is important to review roles, responsibilities, and reporting mechanisms. Ideally, a single source of data across the product life cycle should provide a digital view of each process step, elapsed time, and successful completion of the batch life cycle. There are a variety of software offerings in this area — commonly referred to as orchestration platforms — to evaluate and eventually integrate into the information systems environment. Access to data across the chain of customer, process remediation, exception notification, and guidance in terms of emergency management and contingency planning also should be planned for. This is truly a critical supply chain. However, the benefits at the end of the journey are worth the effort!

About The Author:

Carla Reed is a supply chain professional with more than 25 years of experience providing leadership and program management across a variety of programs for the life sciences industry. Her broad range of experience and expertise has provided solutions for pharmaceutical and biotech companies challenged by the growing complexity of extended supply chain environments. Her firm, New Creed LLC, provides change leadership to facilitate sustainable solutions, providing hands-on experience in all aspects of supply chain operations. You can email her at carla@newcreed.com or connect with her on LinkedIn.

Carla Reed is a supply chain professional with more than 25 years of experience providing leadership and program management across a variety of programs for the life sciences industry. Her broad range of experience and expertise has provided solutions for pharmaceutical and biotech companies challenged by the growing complexity of extended supply chain environments. Her firm, New Creed LLC, provides change leadership to facilitate sustainable solutions, providing hands-on experience in all aspects of supply chain operations. You can email her at carla@newcreed.com or connect with her on LinkedIn.