CMO Management Assessment

Angie Green, former VP of global outsourced manufacturing operations, The Medicines Company

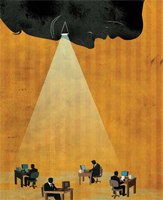

Is your supply chain network running seamlessly? Are your CMOs clear on your company’s goals for the next five years? What is your CMO’s capability expansion plan? An important tool for reducing business risk is having a clear CMO/supplier network strategy. Developing and maintaining those key supplier relationships takes dedicated focus and commitment within your organization. The table below outlines three types of relationship management models: functional, collaborative, and full trust. Find out which model your company emulates. Evaluate your strategic path. Companies that manage CMOs well will directly yield positive results for supply chain protection.

Is your supply chain network running seamlessly? Are your CMOs clear on your company’s goals for the next five years? What is your CMO’s capability expansion plan? An important tool for reducing business risk is having a clear CMO/supplier network strategy. Developing and maintaining those key supplier relationships takes dedicated focus and commitment within your organization. The table below outlines three types of relationship management models: functional, collaborative, and full trust. Find out which model your company emulates. Evaluate your strategic path. Companies that manage CMOs well will directly yield positive results for supply chain protection.

|

Assessment Areas |

Types Of Relationship Models |

||

| FUNCTIONAL | COLLABORATIVE | FULL TRUST | |

| Communication |

Inconsistent and reactionary communication Symptoms are:

|

Communication plan agreed upon up front Symptoms are:

|

Open conversation occurs at all managerial levels Symptoms are:

|

| Visibility And Planning |

Little or no visibility into suppliers’ schedules for our products |

Some visibility into suppliers’ schedule for our products Symptoms are: Data is fairly consistent and reliable. Some surprises. Yields are known. Purchase orders are cut proactively to leverage the needed production slots. Stock-outs and delays are a risk but do not occur with any frequency. |

Full visibility into suppliers’ schedule for our products |

| Short-Term Problem Solving |

Constant tension between customer and supplier Symptoms are: Constant delays, altered production slots, and a lack of momentum overall. Angry conversations and managerial intervention occur frequently. Actions feel forced and reactionary. |

Project management levels aligned with some supervisory guidance Symptoms are: Delays are not common but sometimes occur. Cooperative teams discuss potential roadblocks and often resolve issues quickly. Most issues never reach upper-management. |

Project management teams completely aligned Symptoms are: Frequent communication reduces any short-term problems that impact deliveries or schedules. Project managers are empowered to get the correct experts and managerial resources to resolve problems quickly. Problems are invisible to upper management. |

| Long-Term Problem Solving |

No forum for this type of discussion Symptoms are: A reactionary supply chain with frequent problems leaves no time to discuss any long-term solutions. |

Discussed at annual/semiannual business steering meetings Symptoms are: Project teams identify long-term issues for the next steering meeting agenda. Upper management is not always aware of these issues. Questions and discussion during the meeting lead to more offline discussion. |

Discussed at annual or semiannual business steering meetings and in small managerial groups Symptoms are: All management levels have scheduling clarity on steering meeting frequency, location, and agenda. There is often managerial discussion beforehand, sometimes in a smaller setting first to lay the groundwork for alignment. New strategic opportunities are also discussed. |

|

Summary: Supplier/Customer Relationship |

Your supply chain is at risk. Your process is reactionary with little guidance or cooperation from your CMO.

It is time to sit down and formulate a new strategic mgt. plan in a F2F meeting with your CMO. |

Your company maintains a successful supply chain due to the high level of trust between project management teams.

Get the next level of management aligned on both sides for better results. |

Your product is very well protected because of the openness and visibility into each other’s businesses. People are energized on both sides.

A high level of trust greatly helps the supplier/customer relationship succeed. |