An Industrialization Strategy For Cell Therapies

By Louis Garguilo, Chief Editor, Outsourced Pharma

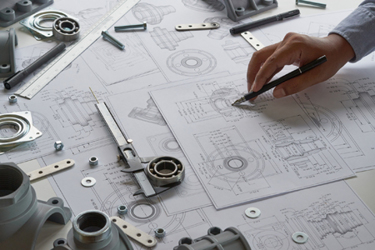

If cell therapy is the art of engineering, the industrialization of these therapies – many of which are stymied by an inability to scale up or produce at various locations –is fully contingent upon the application of engineering concepts and practices.

This we learned in our initial discussion with Vered Caplan, CEO, Orgenesis, Inc. Caplan’s mission is to systematically bring engineering principles to cell-therapy development and commercialization, and enable the widest possible patient access.

Exactly how Orgenesis accomplishes this is the subject of our discussion today.

Orgenesis is a synthesis of therapy developer/commercializer, modern-day service provider, and engineering and supply-chain partner.

One therapy among the current 16 in the Orgenesis clinical trial pipeline, Kyslecel for chronic pancreatitis, “is a wonderful example of what Orgenesis accomplishes,” says Caplan. Orgenesis continues to focus on engineering cells taken from patients who have had pancreatectomy, and become diabetics. The company collects the cells from the pancreas, and “reprograms” them to work positively inside the liver of the patient.

“However, what is the problem with this production currently?” she asks rhetorically. “It is manufactured in only one location, and has various logistical difficulties. Our goal now is to discover a method so it can easily be made at many locations, reduce all the logistics of taking a pancreas out of a patient and getting it back in four hours.”

Kyslecel was licensed by Orgenesis out of a university, and originally developed by a small biotech. “It is now our product, and the aim is to get it to more patients.”

Orgenesis is also looking into use of Kyslecel for other implications. “Maybe you can adapt it for diabetic patients, or other possibilities,” Caplan says, “but first you must solve the engineering challenges.”

“In cell therapy, the bottleneck is typically the engineering.”

Caplan clarifies that Orgenesis itself is not a marketing organization. The company’s goal for products such as Kyslecel is “to demonstrate you can produce cell products wherever you need them, with enough capacity, and at a low enough cost to make them much more widely available.”

To achieve this most broadly, and as we first learned in part one, Orgenesis also serves as an ongoing supply-chain partner to whatever marketer that might acquire the now “engineerable” therapies.

Get To The Point

The tangible manifestation of Orgenesis’ focus on cell-therapy as a function of engineering is called the POCare Platform, designed “to provide a harmonized pathway to commercialize advanced therapies.”

There are three primary components of the platform:

- Identify/partner with early-stage biotechnology developers. Orgenesis brings development/ validation in-house to create a pipeline of owned, licensed, and partnered therapies.

- Work with technology partners to build customized, automated processing systems to streamline therapy production in a scalable GMP-compliant manner at the point of care.

- Utilize a POCare Network that aligns with global academia, research, and hospital partners to enable the development, production, and distribution of a pipeline of advanced therapies directly at the point of care.

“I believe these therapies have enormous implications for all of us,” says Caplan, “but so many companies and organizations can’t scale up or find help.”

As a growing number of developers and sponsors began approaching Caplan, she says, “At a certain point we decided, ‘Okay, we will build the hardware, and place it where it's needed, and we will adapt software so it's user-friendly, and technicians won’t need to be trained nine months to work in a clean room.”

She continues: “Today, in many cases professionals working in clean rooms have PhDs with this great and collective amount of brain power. But instead of standing hours all gowned up and pipetting, you can now utilize them to think – use that brainpower to consider how to reprogram, optimize, analyze, and learn from the data coming out.”

Our industry today has evolved to one creating “great algorithms,” and finding new business models, networks, and supply chains to serve that end, she says.

For example, Orgenesis may work with a research institute to license a therapy the original researchers hope to get out to the widest number of patients possible. That license is essentially for an algorithm for reprogramming a cell.

Orgenesis then builds a closed system that knows how to learn and help implement that program. The closed system becomes an Orgenesis Mobile Processing Unit (OMPUL). Multiple units will make up these OMPUL’s, where all units are qualified as performing alike.

“To be practical, we say ‘point of care,’ because you can put these units right next to or inside a hospital,” explains Caplan.

In other instances, though, and depending on volumes and the specifics of the therapy (e.g., Does it need to undergo freezing?) these products can be produced similar to the way they have been in the past – in a centralized manufacturing facility. Orgenesis itself, or some of its network partners – including CDMOs she named for me and readers would surely recognize – can provide the required supply-chain support.

“If you are making a lot of these products, you have the choice,” says Caplan. “How much do you want to decentralize? You can decide each time for each product.”

“People talk about autologous versus allogeneic. But in many cases, these are combination products. Part of the process is centralized, but the latter stages are completed closer to the patient.

“It's not this clear-cut world. It’s all about having the flexibility to do what's right.”

And continuing to provide leadership – both on the sponsor and service-provider sides – for the creation of a more robust industrialization strategy for cell therapies.