Next Generation Lentiviral Vector Manufacturing Process; Greater Productivity And Enhanced Purity

By Lee Davies, Carol Knevelman, Oliver Goodyear, Ciaran Lamont, Kirstie Pemberton, Maria Kapanidou, George Pamenter, Dan Farley, Jordan Wright, Nicholas Clarkson, Kyriacos Mitrophanous and James Miskin

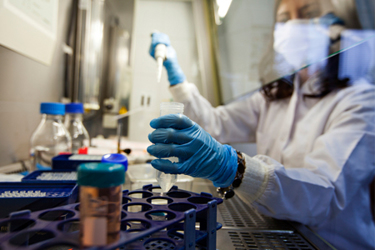

Oxford Biomedica (OXB) has recently introduced a next generation lentiviral manufacturing process incorporating innovative process modifications which simultaneously enhance lentiviral process yields and improve vector quality attributes. Designated “Process C”, this new process takes advantages of advances in perfusion technology to support vector production at higher cell densities than have been associated with traditional batch and fed batch production approaches for lentiviral vectors, allowing for significant process intensification without the need for increased bioreactor volume. Importantly, Process C adopts a plug and play approach facilitating incorporation of small molecule enhancers, some of which have already been identified by OXB. For example, incorporation of U1 (RNA based enhancer) during vector production using Process C led to increased cell-specific productivity. Overall, process yield improvements ranging from 2 to 10 fold have been demonstrated for a range of therapeutic lentiviral vectors with process scalability demonstrated in stirred tank bioreactors up to 200 L in GMP. Process C also incorporates an improved downstream processing approach to specifically target unwanted protein:DNA complexes implicated in vector aggregation. This combined approach has minimised process losses across sterile filtration process steps and has enabled more efficient removal of critical process impurities including plasmid and cellular DNA. Process modifications introduced within Process C significantly increase batch productivity and generate lentiviral vectors with improved quality characteristics including lower levels of residual impurities and an increased proportion of functional vector particles (reduced P:I ratio).

Our new manufacturing platform offers significant benefits for clinical production of lentiviral vectors and will further enable OXB to support the continuing global demand for high quality gene and cell therapy products.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Outsourced Pharma? Subscribe today.