What To Do When Your CMO Implements New Technology (That Impacts Your Product)

By Barbara Berglund, COO, CMC Turnkey Solutions

Your manufacturing CMO has just announced that it is preparing to implement a new technology that will improve quality and save time and money. Now, you just need to figure out if you are able to align the needs of your product or products and get on board with the change. Not only will you need to prepare for the change, but you will need to relay the information and any cost impact to your management team. Innovation and improvement efforts need to consider all aspects of the impact, including quality and regulatory considerations, supply constraints, market constraints, and cost.

Typically, the value of new technology is easy to see; however, the pain involved in implementation is not so easy. After all, there will be regulatory implications, potential impact to quality, impact on product validation and process validation, and there may be a need to perform additional analytical and stability work. This means pulling together different functional groups that will need to contribute expertise and generate rationales and other documents. If the risk of not implementing the technology is large or if the work to implement the technology is insignificant, it will be easier to sell.

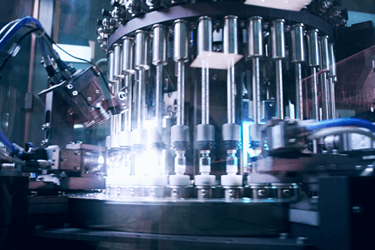

Take as an example a glass depyrogenation process that has been identified as a potential source for particulates. Perhaps the improvement project includes the installation of a new tunnel setup and a minimized human input using robotics and conveyors. However, this installation has a significant impact on the validation status of the filling suite and will also include significant downtime for the line while the new tunnel is installed and validated.

Even if you completely understand the drivers and the need for the new tunnel, this change translates to efforts. What work will need to be done for the product(s)? Will extra batches need to be stockpiled for the downtime? Is there an adequate supply of active and inactive ingredients? Is there a budget for the change in timing? Does the product have the shelf life to support this? What about the vial or syringe; is there adequate glass available for validation work and to maintain the drug supply? Are there media fill implications to the change? Will this change the cost of running the product? Finally, how is this change going to be communicated to the agencies, and how much work will it be for your regulatory group to describe and defend the change and the validation strategy?

Now consider a new technology that includes an inline nondestructive fill weight check. This is an opportunity to reduce time spent performing destructive fill checks and to provide a real-time feedback mechanism to the filling process, avoiding investigation risk for segments of every lot. There is a considerable positive financial potential: instead of discarding two, eight, or more vials at every fill check, all acceptable vials will be saleable; depending on batch size, this may be hundreds of additional units available from every run. From a regulatory point of view, this means greater control is exerted and may even mean that every unit is weighed during the process, reducing or eliminating the risk of missing a low or high fill.

So, what is the pain here? You need to know about the installation process, and whether this means that vials will undergo additional handling before and after the filling operation that could impact the product. Further, you need to understand the reliability of the device and also the software validation that is needed for this work. Also, is the backup plan to continue with destructive fill checks? For the process itself, does the device communicate with the filler, or is there something in between? Will you need to validate the device for your product or for your fill weight? Are there parts associated with the change that are specific to your vial? As with the previous example, will there be downtime during installation and validation, and will this impact the drug supply? Will this change the cost of the run? Your management team may come back with the message: “It is very nice that the CMO is adding this technology, and perhaps we will use it in the future, but we would like to just continue with the manual, destructive fill checks for our legacy products.”

To prepare for the internal discussions, consider the impact of the innovation on every aspect of every product that is affected. A personal meeting with the CMO is helpful in preparing for the discussion, and it is in the best interest of the CMO to retain you as a customer. The cost question will be high on the list to address early; if the innovation will result in a future increased per batch or per vial cost, the management team will want to know how it will benefit from a bottom-line point of view. It might be that there will be fewer rejects, fewer deviations, fewer lost batches, or a better yield from each batch. Perhaps the CMO will offer the innovation without a cost impact for you. From the regulatory point of view, your regulatory team may want the CMO to provide both general descriptions of the change and product-specific strategies and rationales to support communication with agencies. Depending on the innovation and the requirements for validation, the CMO may consider using your components in acceptance testing, qualification, and validation work. In addition, the CMO may be able to offer support in procuring difficult-to-manage components, especially those with long lead times, to mitigate concerns for the clients. Be well prepared for the questions and concerns that will be raised by your management team, and be prepared for the pushback they may give. This also means that a management decision to cease to use a CMO may occur.

Innovation is critical for a CMO to remain competitive and to continuously improve. It is important to be prepared for changes and to be ready to explain and promote improvements in control for pharmaceutical products. Both the CMO and the pharmaceutical organization must constantly balance the need for innovation and the needs of current and future products. Working together through regulatory strategies and dealing with roadblocks and issues is critical for successful implementation.

About The Author:

Barbara Berglund is COO of CMC Turnkey Solutions, where she applies over 20 years of experience in finished pharmaceutical, API, and medical-device manufacturing. In particular, she has direct experience with quality assurance and manufacturing of commercial and clinical-trial sterile liquid and lyophilized parenterals, microencapsulated products, intravitreal products, suspensions, and solid dosage forms. She has held strategic leadership positions in quality assurance, quality control, sterile manufacturing, and project management and has a particular interest in technical transfers both of processes and analytical procedures.

Barbara Berglund is COO of CMC Turnkey Solutions, where she applies over 20 years of experience in finished pharmaceutical, API, and medical-device manufacturing. In particular, she has direct experience with quality assurance and manufacturing of commercial and clinical-trial sterile liquid and lyophilized parenterals, microencapsulated products, intravitreal products, suspensions, and solid dosage forms. She has held strategic leadership positions in quality assurance, quality control, sterile manufacturing, and project management and has a particular interest in technical transfers both of processes and analytical procedures.

Barb has an undergraduate degree in chemistry and postgraduate degrees in chemistry and pharmacological and physiological science. She received her PMI PMP (Project Management Institute Project Management Professional) certification in 2007 and her ASQ CQA (American Society for Quality Certified Quality Auditor) and ASQ CMQ/OE (Certified Manager of Quality and Operational Excellence) certifications in 2015.